Benelli Armi SpA - The Maker of Benelli Shotguns in Urbino, Italy

| Quick Navigation: | History | Factory Details | In-Line Inertia Driven System | Guns of Benelli | Factory Videos | Sporting Arms |

| Benelli Armi SpA, which started in 1967 and is headquartered in Urbino, Italy, is the Italian company behind Benelli shotguns. The following company profile was compiled after a visit to the Benelli factory in Urbino, Italy by our GunsForSale.com team. |

History

Benelli shotguns are generally regarded to be among the world's best, but the initial "Inertia" design for the Benelli semi-automatic shotgun, conceived by inventor Bruno Civolani, was initially rejected by many gunmakers. How, then, has a relatively young, upstart company - founded in 1967 - grown to become a force to be reckoned with in the shotgun market?

Benelli shotguns are generally regarded to be among the world's best, but the initial "Inertia" design for the Benelli semi-automatic shotgun, conceived by inventor Bruno Civolani, was initially rejected by many gunmakers. How, then, has a relatively young, upstart company - founded in 1967 - grown to become a force to be reckoned with in the shotgun market?

Well, the company had a bit of a head start, because the Benelli family was already established in the motorcycle manufacturing business. Thus, they had a pool of knowledge and expertise to draw from when developing and manufacturing their new shotgun. Benelli Armi became so successful that it eclipsed the motorcycle business, especially after increased Japanese competition, and the Benelli family began to sell shares of Benelli Armi to prop up Benelli Motorcycles; this effort failed and both businesses eventually left the Benelli family.

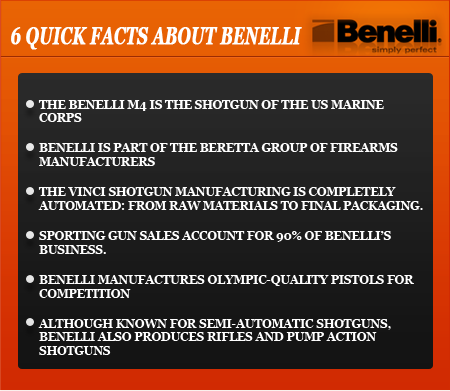

Benelli Armi was acquired by Beretta, a piece at a time, until the process was complete in the early 1990s. Beretta chose to give Benelli free rein, with two major stipulations - the first being that Beretta would produce all of the barrels for Benelli. In this way, Beretta closely protects technological secrets while also keeping tabs on exactly what Benelli is producing, for every Benelli shotgun must have a barrel. Benelli benefits from this in that Beretta is a very large and skilled barrel maker. Benelli customers benefit because they receive shotguns that have cryogenically treated, hammer forged, chrome lined barrels, which are premium features.

The second condition was that Benelli would stop producing defensive handguns (as seen in the display case on the right), which were proving to be quite competitive for Beretta's own products. This was disappointing to Benelli aficionados, but it did allow the company to focus on its core business: semi-auto shotguns.

Benelli Factory

Benelli's technologically advanced factory in Urbino, Italy, regularly produces 800 firearms per day. This number could be increased to 1000 if only a few models were produced, but Benelli's success is due in part to the wide variety of weapons they produce - 135 at the moment. All production is completed by advanced machinery which is also used by automakers such as Toyota, and Benelli constantly updates its machines and equipment.

Benelli's technologically advanced factory in Urbino, Italy, regularly produces 800 firearms per day. This number could be increased to 1000 if only a few models were produced, but Benelli's success is due in part to the wide variety of weapons they produce - 135 at the moment. All production is completed by advanced machinery which is also used by automakers such as Toyota, and Benelli constantly updates its machines and equipment.

Assembly, though, is mostly done by some of Benelli's 180 factory workers. A notable exception is Benelli's new Vinci shotgun, the manufacturing of which - from processing of raw materials to final packaging - is entirely automated. This is in keeping with Benelli's ISO 9001 and 14001 as well as NATO certifications, though as ISO certified facilities go, cleanliness and precision are taken to exceptional levels at Benelli.

The majority of Benelli's production consists of hunting or competition weapons, with the tactical and law enforcement market only forming 10% of sales. Still, sales such as the M1014 Joint Combat Shotgun to the United States military showcase the high level of quality that all Benelli products have. The robots in the Urbino factory don't know if they're making bolts for a Super Black Eagle or an M2/M4 combat shotgun - the attention to detail is the same. Even tool wear is closely monitored, and worn tools are automatically replaced by the robots.

Benelli also produces target pistols for Olympic competition, though the primary reason for this is not the first thing that would come to mind - many countries don't allow advertising of weapons like shotguns, but target pistols don't have such restrictions, and they are a vehicle for Benelli to advertise itself as a company in such markets. Although 1/3 of sales are to the United States, the company aggressively pursues new markets such as Russia and Turkey. Russia, for example, accounted for 8% of the company's sales in 2008.

The big draw to Russian customers is that Benelli shotguns work. The inertia operating system is exceptionally reliable and has fewer parts that need replacement or are likely to break. For a hunter living in the far reaches of Siberia who only comes to a major urban center once or twice a year, this is a huge feature, and a reason to avoid gas-operated shotguns that require higher maintenance.

Benelli also manufactures pump-action shotguns - the vast majority of which are sold to the United States - and semi-auto rifles. These products make up a small portion of Benelli's sales, but receive no less attention at Urbino.

Benelli continues to gain market share in the United States and abroad, in the face of stiff domestic and international competition. This is a testament to the high quality of every Benelli product.

In-Line Inertia Driven System

The Benelli In-Line Inertia Driven System is a four step process: chambering, firing, recoil and ejection.

The Benelli In-Line Inertia Driven System is a four step process: chambering, firing, recoil and ejection.

Chambering – As the bolt assembly moves into battery, the locking head pin moves along a curved track in the bolt body to rotate the steel bolt head into engagement with the steel barrel extension.

Firing – When the trigger is pulled, every part of the shotgun except the bolt body moves rearward. The curved track in the bolt body, which is moving forward relative to the rest of the gun, presses against the locking head pin, turning the bolt head even tighter into the barrel extension. At the same time, the inertia spring is compressed between bolt head and body. The cartridge drop lever moves up, allowing a shell to move from the magazine to the carrier.

Recoil – Near the end of the recoil cycle, chamber pressure drops to a safe level and the gun’s rearward motion slows. The heavy inertia spring then thrusts the bolt assembly rearward, unlocking the rotating bolt head, extracting the spent shell from the chamber and pulling it against the ejector.

Ejection – As the empty shell exits the receiver, the energy of the moving bolt assembly re-cocks the hammer and compresses the recoil spring. The recoil spring then thrusts the bolt assembly forward, lifting the on-coming shell into position and chambering a fresh cartridge. The gun is ready to fire again in a fraction of a second.

Guns of Benelli

Vinci

The Benelli Vinci was developed to be the “fastest-shooting, softest-kicking, most reliable” 12 gauge shotgun ever made.

The Vinci is a semi-automatic hunting shotgun that uses the revolutionary In-Line Inertia Driven System. With the ComfortTech Plus stock, the Vinci is measured to have up to 72% less felt recoil than conventional semi-automatic shotguns.

The Vinci uses a modular design, allowing for easy disassembly, cleaning and reassembly. The shotgun breaks down into three components: the barrel/receiver module, the trigger group/forearm module and the buttstock.

Vinci shotguns can be had in black, Realtree APG and Realtree MAX-4 finishes. Barrel lengths of 24 – 28” are available.

Nova

The Nova line of shotguns are one of Benelli’s entries into the pump gun market. Benelli claims the Nova is a 21st century shotgun, sporting many modern features for the outdoorsman.

The Nova uses corrosion proof polymer over-molded on a skeleton framework to form a one-piece receiver and buttstock.

The Nova line has many options including choice of gauges (12 or 20), standard or youth length of pull and finishes including black, Realtree APG and Realtree Max-4. Barrel lengths range from 24” to 28” in the Nova line.

M4 Tactical

The Benelli M4 Tactical shotgun is a 12 gauge, semi-automatic smoothbore. The M4 uses the unique ARGO system: Auto Regulating, Gas Operated. The ARGO system uses dual stainless-steel pistons that operate directly against the bolt assembly for ultra-reliable function in adverse conditions.

The M4 is the choice of the US Marine Corps and has been proven in combat.

Available in both black and a desert camo pattern, the M4 comes standard with a Picatinny rail on the receiver for optics. In addition, the M4 comes with ghost-ring sights for quick, accurate shooting without the addition of glass.

Benelli Factory Videos

Ammunition for Benelli Shotguns

- 12 gauge shotgun shells

- 16 gauge shotgun shells

- 20 gauge shotgun shells

- 28 gauge shotgun shells

- 32 gauge shotgun shells

- 410 shotgun shells