Fabbrica d'Armi Pietro Beretta SpA - Home of Beretta Firearms in Brescia, Italy

| Quick Navigation: | History | Factory Details | Quality Control | Military & Tactical Firearms | Factory Videos | Sporting Arms | U.S. Citizen Firearms |

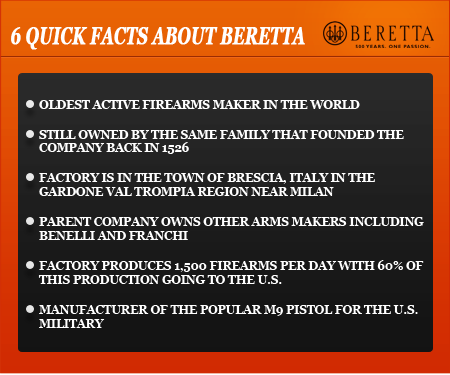

| Fabbrica d'Armi Pietro Beretta SpA, Home of Beretta Firearms in Brescia, Italy, is the world's oldest firearms manufacturer in existence today. The following company profile was compiled after a visit to the Beretta factory in Gardone, Italy by the GunsForSale.com team. |

The Beretta Holding Group, controlled by the Beretta family, owns firearm manufacturers Beretta, Benelli, Franchi, Uberti, Sako, and Stoeger, as well as their international distributors and subsidiaries, and the optics manufacturer Burris.

Fabbrica d’Armi Pietro Beretta S.p.A. manufactures 1,500 firearms per day, 85% of which are sporting arms. The company is located in the village of Gardone Val Trompia, in northern Italy.

In addition to its sporting pedigree - more Olympic Games, World Championships and international competitions have been won with Beretta shotguns than any other - Beretta supplies arms to militaries and police forces across the globe. One of its most prestigious contracts is with the United States Military, to which Beretta has provided the M9 handgun since 1985.

History of Beretta Firearms

Beretta Armi is the oldest continuously operating firearm manufacturer in the world, having received its first recorded order, from the Arsenal of Venice, in 1526:

"Today, October the 3rd to Master Bartholomew Beretta from Gardone, in Brescia region, for 185 barrels for harquebus, to our House of the Arsenal, 296 ducats have been given."

The company has remained under the control of the Beretta family since that time - fifteen generations in total - and the family is very active in the day-to-day operations of the business. Today, the company is run by Ugo Gussalli Beretta and his two sons, Pietro and Franco.

Beretta's Factory

Gardone Val Trompia is a small comune (township) approximately ten miles north of Brescia, Italy. Mountains crowd Gardone on what seems like all sides, and a small river runs through parts of the town. It could hardly be described as more than a quaint village, and yet, some of the world's largest and most prestigious firearms manufacturers are located here - including the nearly 100,000 square meters of factory space occupied by Beretta. The Beretta factory is broken up into smaller elements, some connected by bridges that cross streets and the river, others that are located a short distance away, but still within the town.

Perhaps the most visually impressive element of the Beretta factory - or, for that matter, in the town - is the Beretta Mansion. Constructed in the 19th Century to house the Beretta clan, today it serves many functions, from greeting visitors to the company and providing an exclusive environment for business discussions to containing the Beretta Museum.

The many different buildings used for production, assembly, and administrative purposes can be divided into three different groups. Beretta labels the first "Casa Beretta," which includes the mansion, and the second "Beretta Uno," the older, and larger, section of the factory, containing most production and almost all assembly areas, and is currently composed of 67,360 square meters of covered space. The third compound is labeled "Beretta Due," and is a newer expansion in the southern part of the town. It houses some production facilities, as well as the master engravers who produce Beretta's premium firearms, and contains 20,640 square meters of covered space.

Because space is at a premium in Gardone, Beretta has in some cases expanded vertically. Although the heaviest materials and machinery must remain on the ground floor, assembly operations are divided into firearm categories and assigned to various floors of one of the main factory buildings. For example, one floor is dedicated to side-by-side and over-under shotguns such as the 686, 687, DT10, and Ultralight, while another assembles only semi-automatic shotguns such as the AL391 and A400 Xplor. All other Beretta automatic firearms, including the 92FS, PX4, CX4, and ARX-160, are assembled on a separate floor.

Despite the stability of being owned and managed by the same family for centuries, Beretta's manufacturing processes have been in a constant state of change for over 150 years, as it adopted the newest and most efficient theories and practices.

Beretta was one of the first companies in Italy to introduce numerical control machines, in 1976, and it did so in a big way: by buying an Italian company, MI-VAL, that manufactured these machines. MI-VAL is still part of the Beretta Group, and produces many of the machines used by companies within the group.

In the 1980s, Beretta introduced CAD/CAM (computer aided drafting/computer aided manufacturing) to its facilities, and later CIM (computer-integrated manufacturing). One of the biggest advantages of computer-controlled machinery is that tool changes are done by the machine itself, or in some cases, by robots that tend to the machines. This enables a more efficient workflow, for in the past, tools had to be changed by hand, and were thus subject to the vagaries of humanity.

In addition, the machines can work around the clock, requiring little supervision. In the event of a problem requiring human attention, the machines at Beretta can telephone a human supervisor at his home in the middle of the night - but this does not happen often.

Given the company's emphasis on technological innovation, efficiency, and reducing the number of employees on the production floor, one might think that the craftsmanship required to produce matchlock and flintlock firearms in years past had been lost, surrendered as unnecessary in the face of robots and computers. This, however, is far from the truth - Beretta still produces some of the most sought-after custom engraved firearms in the world.

Away from the premium line of hand-engraved shotguns and express rifles, Beretta's standard field and competition over-unders still receive two hours and twenty minutes of hand fitting by Beretta craftsmen. Each man - or woman - assigned to these tasks completes them with rapt attention and the practiced movements that come only with experience.

The atmosphere at Beretta is one of family - not only of the Beretta family, but of the many families that have several members working at the factory, and the company itself as one large family. It is not uncommon to see a mother and daughter taking a lunch break together, or an uncle and a nephew. The majority of Beretta employees are local to Gardone and some are second- or third-generation employees.

Of the 860 Beretta employees in Gardone, 680 work in production, with another 180 divided evenly among marketing/sales, research and development, and general services. Although the company has bet - and won - on technological improvements, the backbone of the company has been, and will continue to be, the employees.

Quality Control at Beretta

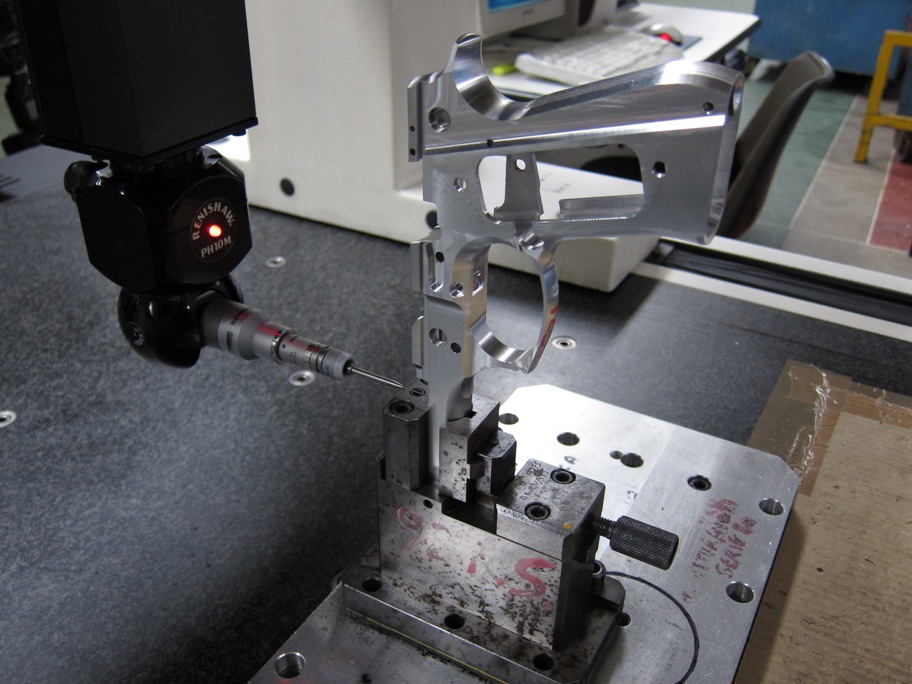

For Beretta, quality control is very important. It does the company no good to waste material on parts that don't conform to standards, and it's cheaper to build the right product the first time than it is to build a shoddy product that must be replaced or repaired.

Beretta uses a number of computerized measuring machines (CMMs) which precisely measure the dimensions of components at various stages of manufacture. For example, frame forgings can be checked for dimensional accuracy before any machining is done.

After the assembly phase, barcodes and laser scanners are used to record each quality control inspection performed by a human employee, who follows a strict checklist. This information is permanently stored in a computer database, which can be referred to in the unlikely event of a warranty issue.

Similarly, the results of functional and accuracy testing, which all Beretta firearms undergo, are recorded as well. Each firearm must function flawlessly and meet accuracy standards, or it will be returned to the production/assembly area for inspection and possible repair.

Military and Tactical Firearms from Beretta

Beretta ARX160

The Beretta ARX160 is Beretta's newest 5.56mm carbine. It was developed by Beretta as part of Italy's Soldato Futuro, or Future Soldier, program. It has been adopted by the Italian armed forces, replacing Beretta AR70/90 rifles that had been in service for decades.

The Beretta ARX160 is Beretta's newest 5.56mm carbine. It was developed by Beretta as part of Italy's Soldato Futuro, or Future Soldier, program. It has been adopted by the Italian armed forces, replacing Beretta AR70/90 rifles that had been in service for decades.

The ARX160 is a lightweight, gas operated, air cooled, magazine fed carbine that fires from a closed bolt. Production models are chambered in 5.56mm NATO and feature 12" and 16" chrome lined, hammer forged barrels, with a twist rate of 1 turn in 7 inches. Other calibers are available, including 5.45x39mm 7.62x39, and 6.8mm SPC. The 5.56mm carbine uses STANAG (M16) magazines.

Ambidextrous operation of the ARX160 was a primary design consideration for Beretta. Controls such as the magazine release, bolt catch/release, and safety/selector switch are easily accessible, whether the weapon is being fired from the left or right shoulder.

The charging handle reciprocates with the action. It is possible to reverse the position of the charging handle in only a few seconds, and without disassembling any part of the carbine. Because the ARX160 ejects brass from the side opposite the charging handle, left-handed shooters will not have brass ejecting towards their face.

The ARX160 has been designed with reduced end user maintenance requirements in mind. Takedown of the modular system is quick and simple. In addition, according to Beretta, the ARX160 has been "engineered to require minimum lubrication, while providing maximum reliability in the most extreme conditions."

Changing barrels, whether to replace a worn example or to switch from long to short or vice versa, is exceptionally simple. The process takes seconds and requires no tools whatsoever - the bolt is locked to the rear, two locking tabs on the side of the receiver are held down, and the barrel - with gas block assembly and piston/op-rod - is pulled forward. Reassembly proceeds in reverse order.

Capable of both semi-auto and full-auto fire, the ARX160 features an ambidextrous "short throw" selector switch, with only 82 degrees of rotation from "on safe" to "full auto." The cyclic rate of fire of the weapon is 700 rounds per minute.

To allow the attachment of modern optoelectronic sights and other accessories, the ARX160 features a MIL-STD 1913, or Picatinny, rail that runs along the full length of the top of the receiver and handguard, and also has shorter, removable rail sections on the sides and bottom of the handguard. Folding sights are standard, and the rear sight is adjustable for windage and elevation out to 600 meters.

With a stock that folds as well as collapses among four positions, the ARX160 can be easily adjusted for soldiers of different size and stature, the use of body armor or other gear, and transport in the tight spaces of a helicopter or armored personnel carrier. Folding the stock does not prevent the weapon from being fired. To enable multiple sling configurations, six sling attachment points are designed into the weapon.

The weight of the ARX160 with 16" barrel is 3.1kg (6.8lbs) unloaded. With the stock folded, the overall length of the ARX160 is 26.75" (680mm); unfolding the stock increases length to 33.66" (855mm). The range of adjustment of the collapsible stock is 2.5" (65mm), providing a maximum overall length of 36.25" (920mm).

Beretta has also designed a 40mm grenade launcher, the GLX160, that integrates well with the ARX160, but can also be used as a stand-alone system.

Beretta MX4 Submachine Gun

Similar to the Cx4 Storm, the Beretta Mx4 is a select fire pistol caliber carbine chambered in 9x19mm. It is intended for the law enforcement and military market worldwide. It features a 312mm (12.28") hammer forged, chrome lined barrel and a standard 30 round magazine, although it can accept shorter magazines meant for use with Beretta handguns. The weapon has a three position selector, with safe, semi, and auto positions available. The weight of an unloaded Mx4 is 5.5lbs, or 2.5kg.

The Mx4 has integral iron sights and a top picatinny rail for attachment of optics, lights, and lasers. Its compact overall length (25") makes it more suitable for use in compact spaces or for personnel operating from vehicles than larger weapons, and it is light enough to be easily carried by even those who are not normally called upon to carry long guns on duty.

In 2011, the Indian Ministry of Home Affairs ordered 34,500 Mx4s. The €25 million contract specifies delivery of the firearms within 12 months.

Beretta Cx4 Storm Carbine

Beretta's Cx4 Storm carbine was introduced to the US market in 2003, and has proven to be very popular. It offers owners of various Beretta handguns the ability to use their existing magazines in a carbine-sized weapon that offers greater accuracy, range, and shootability.

Available in 9x19mm, .40 S&W, and .45 ACP, the Cx4 weighs just 5.75lbs unloaded. It comes with a fixed stock, required due to US import laws, but the length of pull is adjustable from 13.25" to 15" with the use of spacers, which are included with the firearm. The stock has an integral sling loop on both sides.

Designed with ambidextrous operation in mind, the Cx4's crossbolt safety and magazine release controls can be reversed for right- or left-handed use. In addition, the bolt can be configured for ejection of spent cases out the right or left side of the weapon without the use of tools.

There are currently four Cx4 carbine configurations available in the United States. The .45 ACP carbine takes 8rd Beretta Cougar magazines. The .40 S&W version uses 14rd Px4 Storm magazines. There are two 9mm versions, the only difference being the magazines used - one is configured for use with Beretta 92 series magazines, and comes with 15rd magazines standard, and the other uses 9mm Px4 Storm magazines, and comes with 17rd magazines standard.

Beretta M9 Pistol

History

In the early 1980s, the US Armed Forces set out to acquire a new handgun to replace the venerable 1911 that had been in service for seven decades. Competition from Sig Sauer, Smith & Wesson, Heckler & Koch, Steyr, Fabrique Nationale, and Walther was fierce, but only the Sig Sauer P226 and Beretta 92F satisfactorily passed all of the rigorous testing during the XM9 handgun trials in 1984.

Because Beretta was able to produce the 92F for a lower cost than the P226, Beretta was awarded the contract, and has supplied all branches of the US military with sidearms since. It is interesting to note that the Model 92 won not only the 1984 XM9 trial, but also a previous trial, the Joint Service Small Arms Program, held by the Air Force in 1979, and the XM10 trial, held in 1989. This last trial was held as a result of Congressional intervention after reports of early Beretta M9 failures caused alarm.

Though very few in number, the failures were quite spectacular - the rear portion of the slide would separate from the weapon while firing, traveling rearward and generally striking the face of the shooter. After a thorough search of government documents done by SightM1911.com, 14 cases of slide failure were found in the very early (pre-April ’88) M9/92 slides.

Of those fourteen failures, only three occurred outside laboratory testing. This testing resulted in a design change - the addition of a device to stop the slide from traveling too far to the rear - and no failures have been noted since that time. The revised pistol was named the 92FS, but the military designation, M9, remained the same.

It was a condition of the XM9 trial that production be located in the United States. Because it already had a facility in Accokeek, Maryland, Beretta chose to expand operations there rather than open a new facility. Accokeek is currently the home of Beretta USA, which produces firearms for the US market, in addition to importing Beretta firearms made in Italy.

Design/Specifications

The Beretta M9 is a semi-automatic pistol chambered in 9x19mm NATO. The frame is forged 7075-T6 aluminum, with type III hard anodizing, and the slide is carbon steel, treated with Beretta's Bruniton finish. Barrels are chrome lined carbon steel, with Bruniton finish, and their rifling is created using the broach cut method.

The firing system used by the Beretta M9 is known as double action/single action, or DA/SA. With this system, the first trigger pull is long and heavy, while each subsequent trigger pull is short and light. The pistol has a slide-mounted ambidextrous safety and decocker. When activated, the hammer is safely lowered without discharging a round, and the firing pin is rotated out of line with the chamber, making it impossible for the weapon to fire.

The M9 uses a double-stack magazine with a capacity of 15 rounds, although extended 20-round magazines are available, and Beretta is now producing 17-round magazines for the new 92A1 variant, which fit and function perfectly in the M9. The newest M9 magazines have a physical vapor deposition (PVD) coating that repels dust and has other modifications to improve reliability in sandy conditions.

According to Beretta, the Mean Rounds Between Stoppage (MRBS) for the Beretta M9 is 17,500 rounds. In other words, the pistol is not likely to malfunction even once during that time. In addition, the minimum lifespan for the major components of the pistol is at least 22,000 rounds, with locking block replacement being recommended at that time.

The front and backstrap of the M9 are serrated to improve grip, but the newest M9 variant, the M9A1, takes that a step further with aggressive checkering on both the frontstrap and backstrap. In addition, the M9A1 features a picatinny rail, integral to the frame, which allows the use of a small pistol light or aiming laser.

The Beretta M9 weighs 33.3 ounces unloaded and 40.9 ounces loaded; the M9A1 variant's picatinny rail adds 1.6 ounces. Both feature a 4.9" barrel.

Beretta 93R Pistol

The Beretta 93r is a select fire pistol based on the popular Beretta 92 handgun. The 93r allows the user to fire either single shots or three round bursts.

The 93r was typically fitted with an extended, 20-round magazine, as well as a compensated barrel and removable shoulder stock. Later models did not have the ported barrel.

Forward of the trigger guard was a folding foregrip to assist with controlling recoil. Like many submachine guns, the Beretta 93r was chambered in 9mm.

The Beretta 93R has seen limited use with protection details and specialized law enforcement and military units, and is no longer in production.

However, the 93R has proved popular in pop culture, making numerous appearances in movies and video games. A modified 93R was used as the primary sidearm of the main character in the RoboCop series of movies.

Beretta Sporting Arms

Beretta manufactures high end military and law enforcement firearms, but their largest business is in the sporting industry. Sporting guns make up approximately 85% of their manufacturing. Of the approximately 1,500 firearms that come out of the Italian manufacturing facilities, more than half are destined for the United States.

In the sporting gun market, Beretta holds a stellar reputation for their shotguns. Manufacturing semiautomatics, over-unders and side by sides, Beretta has earned their way into the hands of shooters and hunters everywhere.

Not content to rest on past performance, Beretta continues to develop new long guns for the sporting market. Designs like the A400 Xplor semi-auto shotgun push the edge of high performance hunting and shooting farther along.

Beretta also has a strong presence in the personal protection market. The PX4 series of handguns are considered some of the best pistols on the market, available in various calibers and sizes.

Introduced in 2010, the Beretta TX4 Storm shotgun is proving to be a capable home defense firearm. This semiautomatic shotgun features superb sights and holds 5+1 shells of potent 12 gauge ammo.

Beretta Factory Videos